ALL IS HERE JUTS READ FOLLOW

http://buildingmaterials.com.my/structural-materials/purlin/

What is a Purlin

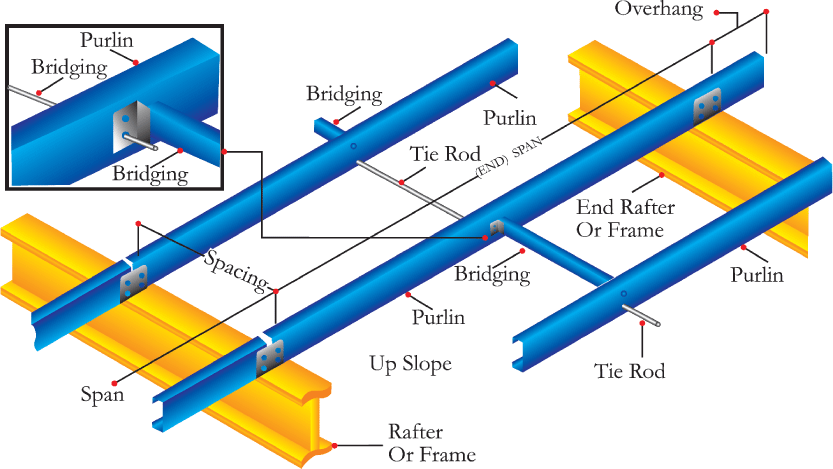

A purlin, historically called a purling, perling, purline or purloyne is a horizontal beam or bar used for structural support in buildings, usually any longitudinal, horizontal, structural member in a roof.

Purlins are supported either by rafters or the walls of the building. The purlins of a roof support the weight of the roof deck. The roof deck is the metal sheeting, the wood panel or the ply board that creates the surface of the roof.

Types of Purlin

There are several kinds of purlins and are divided into different categories based on their material and shape. Different purlins have different uses.

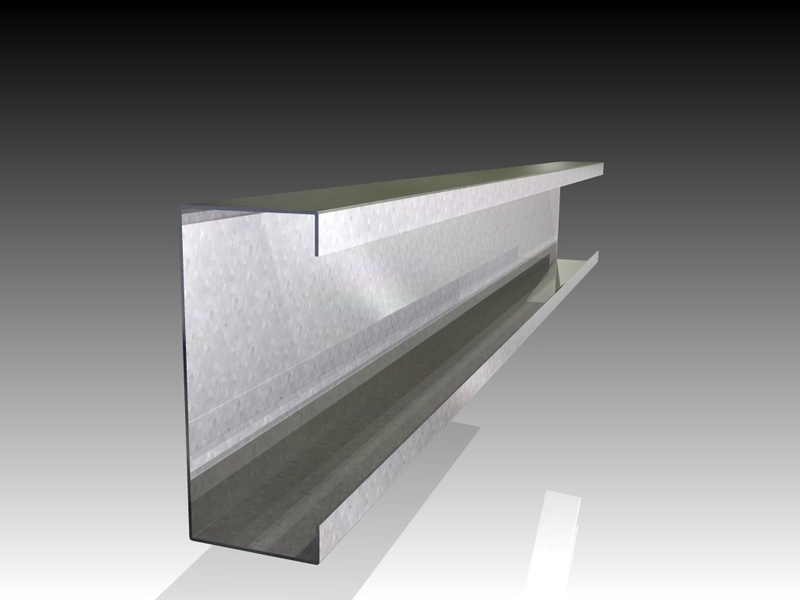

Example of a C Purlin

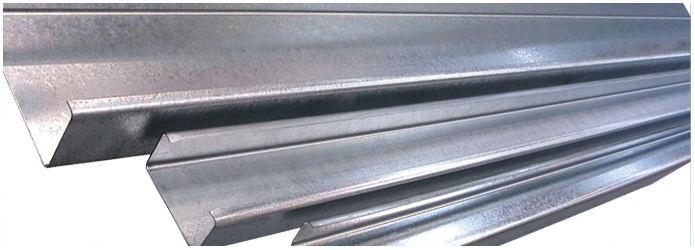

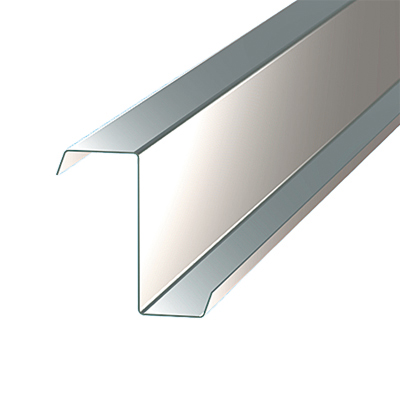

Examples of a Z Purlin

Purlins can be made from solid beams of wood but the steel purlin is most commonly used in roofing, made fromcold-formed steel that is thin enough to insert screws through.

Cold steel is made by pressing thin sheets of steel into their suitable shapes and is stronger than hot-formed steel and less costly. In steel construction, the term purlin commonly refers to roof framing members that span parallel to the building eave and support the roof decking or sheeting.

The purlins are in turn supported by rafters or walls. In steel construction, secondary members such as purlins (roof) and girts (wall) are frequently C, Z or U sections, (or mill rolled) C sections.

Cold-formed steel can be efficient on a weight basis relative to mill rolled sections for secondary member applications.

Applications of Purlin

Steel Type

There are 3 types of steel purlins. In the construction of the roofs, the rectangular hollow section is used where the support structure is visible when the construction is complete and the rectangular shape makes the roof aesthetically better looking.

The C purlins are shaped like a squared-off letter C and commonly used for structural support in walls, roofs and as floor joists. C purlins are also used to form braces, columns or ties in sheds.

The Z purlin is shaped like the letter Z and also commonly used in walls or for large roofing projects. Their shapes gives it the flexibility to overlap with others at the joints to form structurally stronger and continuous beams across multiple supports and are thus stronger than the C purlins.

Additionally the Z sections can be nested for more efficient transportation and, on the building, lapped at the supports. Visualisations can be seen in image below.

Wood Type

In traditional timber or wood construction, the three basic types of purlin are the plate, the principal and the common.

The common purlins are typically “trenched through” the top sides of the principal rafters and they carry vertical roof sheathing or vertically laid boards with seams covered with battens.

Purlin plates are major horizontal beams which support the mid-span of rafters and are supported by posts. When the rafters are supported, this allow for longer spans than the rafters alone could span so wider buildings can be constructed.

Principal purlins are also called “major purlin” or “side purlin”. They are supported by principal rafters and support common rafters and further classified by how they connect to the principal rafters.

“Through purlins” pass over the top of the principal rafters but “butt purlins” are tenoned into the sides of the principal rafters whereas the “clasped purlins” are those that are clutched by a collar beam.

Confusing? Just refer to image below as a sample, but of course configurations vary according to designs too.